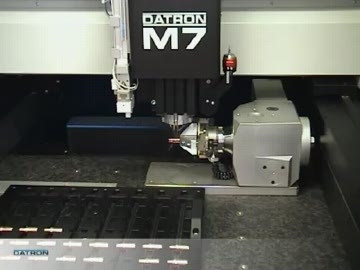

DATRON M8Cube High-Speed Machining Center - Milling Mold for Radio Controlled Quadrocopter - Центр с ЧПУ

Описание

Продолжительность: 06:59

Visit for more info. This video shows a German-engineered M8Cube machining center milling a mold for a the production of a radio-controlled Quadrocopter. The M8Cube features rushless, direct drives provide faster acceleration, feed rates up to 866 inches per minute and shorter cycle times. A 3kW, 40,000 RPM, liquid-chilled spindle delivers greater horsepower for heavier machining, as well as the flexibility to mill a wide range of materials. HSK-E 25 tool holders offer precision and 1 micron run out. At a time when shop floor space is at a premium, the M8 Cube has a footprint of only 69" x 69". At the same time, it features a large work area of 40" x 28" x 9" (X,Y,Z). This allows for multiple setups and accommodates DATRON's integrated work-holding systems, automation and rotary axes -- all combined and configured to meet the exact needs of the M8 Cube is controlled by a dynamic Windows-based software that has the flexibility to integrate with third-party software and automation systems. Operation indicator lights built in to the gantry and control provide visible machine status eliminating the need for additional light sticks. Other options include a spray-mist coolant system, integrated 3D probing and automatic tool changers with up to 30 stations and tool-length sensing. The M8 Cube is ideal for precision, high or low volume production of electronic, aerospace and medical parts, as well as industrial engraving applications.

![Гибка листового металла - методы и советы по проектированию [часть 1]](https://www.prostanki.com/img/partners/JXcgdg3Wz1Htcxk3MBOE.jpg)